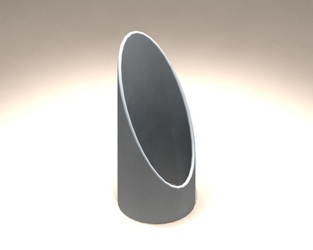

Pedrazzoli 40 Multi-Hit Tube End former- 40 mm diameter Max diameter

Versatile used and fully functioning tube ram end former.

This machine can perform 1,2,3 or 4 hits.

Tool station can shuttle left to right and top to bottom.

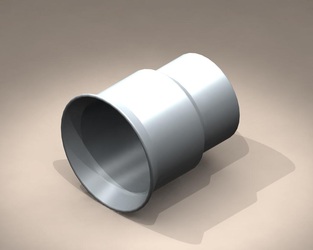

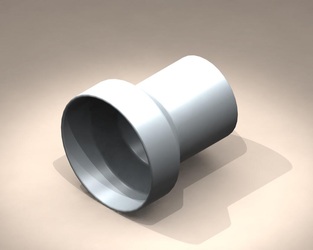

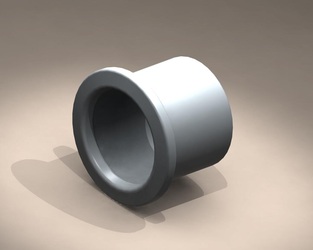

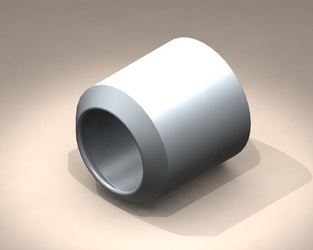

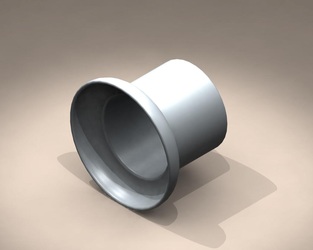

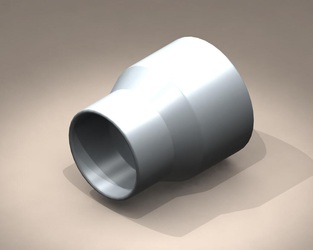

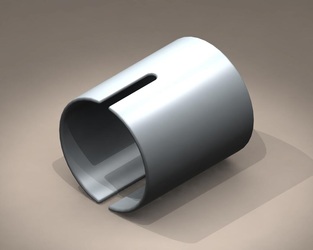

Expand, reduce, curl, flange and custom shape the tube.

For full details of machine and tooling please download file at the bottom of the page.

Price on request.

| ped_40_end_former_details.xls | |

| File Size: | 16 kb |

| File Type: | xls |

"SORRY SOLD "

EAGLE EATON LEONARD

C-Frame

with 4 station

linear shuttle

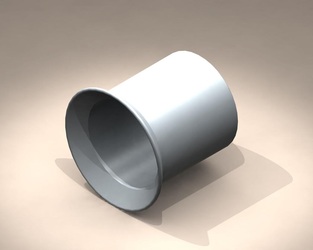

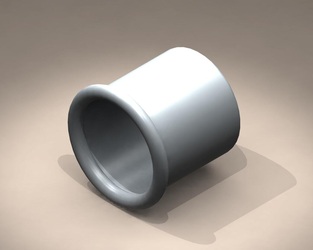

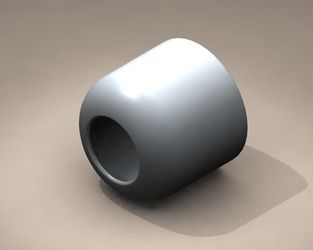

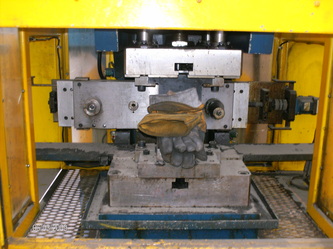

C-frame tube end former with 4 station shuttle

With a 24 ton clamp force and a 12 ton ram force this machine is a heavy duty tube end former.It comes with a programmable 4 station shuttle. You choose from 1,2,3 or 4 hits. This allows a multitude of shapes to be created in 1 clamp.

It can work with tube diameters up to 125 mm, and it is designed so additional operations can be configured around the central working zones, to allows as many operation as possible to be executed in 1 clamping of the tube.

In the video shown below, the model CFR.24/12 has been set up to produce the the body of a tail pipe for an automotive exhaust. It end forms the tube 3 times,{stepped reducing}and then puts a timing notch in. Finally a trim blade operates from the side to create an angle cut. After the body has been produced on the C-frame it was passed to standard Eagle E machine {ram former} where it is curled. The C-frame is easy to re-tool for other applications. This machine is very versatile in its design. Because of it open access on 3 sides it can handle the most difficult of bent tubes, that need to be end formed.

It can work with tube diameters up to 125 mm, and it is designed so additional operations can be configured around the central working zones, to allows as many operation as possible to be executed in 1 clamping of the tube.

In the video shown below, the model CFR.24/12 has been set up to produce the the body of a tail pipe for an automotive exhaust. It end forms the tube 3 times,{stepped reducing}and then puts a timing notch in. Finally a trim blade operates from the side to create an angle cut. After the body has been produced on the C-frame it was passed to standard Eagle E machine {ram former} where it is curled. The C-frame is easy to re-tool for other applications. This machine is very versatile in its design. Because of it open access on 3 sides it can handle the most difficult of bent tubes, that need to be end formed.